Welcome To The Third Dimension - Saddle Edition

3D printing technology is nothing short of amazing. In a world where the term “modern marvel” has become a little cliche, 3D printing legitimately qualifies. 3D printing technology has given us advancements in everything from medical applications to commercial manufacturing, and good news for us, this includes the cycling industry. Thanks to 3D printing, manufacturers and designers have not only been able to slash timelines in prototyping and testing, but also radically manipulate the material used to construct some of the products we use. This amazing technology has already started to revolutionize much of our modern world, and arguably one of the best applications of it has shown up where many might have least expected it. If you’re not yet sitting on a 3D printed saddle, chances are you might be at some point!

You 3D printed my what??

In addition to “hard” items such as computer mounts, headset adapters and clamps, 3D print technology has also recently been applied to a new crop of bike saddles, in what might be the biggest step forward in saddle comfort that we’ve seen in years. Via the 3D print process, designers are able to infinitely tune the structure of the saddle surface in a way that is impossible with traditional foam. Consisting of a wild looking, mostly open-matrix polymer, the printed outer layer of the saddle maps the padding density in a way that both reduces pressure in the sit bone area, and still provides appropriate cushioning (such as at the nose of the saddle) to help prevent numbness. Lower padding density at sit bone contacts lets the saddle support your weight almost like a hammock, with higher density padding in the surrounding areas providing necessary support. This design reduces peak pressure at the sit bones, yet still keeps the pelvis stable and dampens vibration at the same time. The result is a saddle that can increase comfort, improve performance and help reduce the chance of injury to sensitive tissue areas. Now that 3D saddles have been on the market for a few years, improvements have been reported from riders of all genders and across the cycling spectrum (on-road and off).

Meet the players

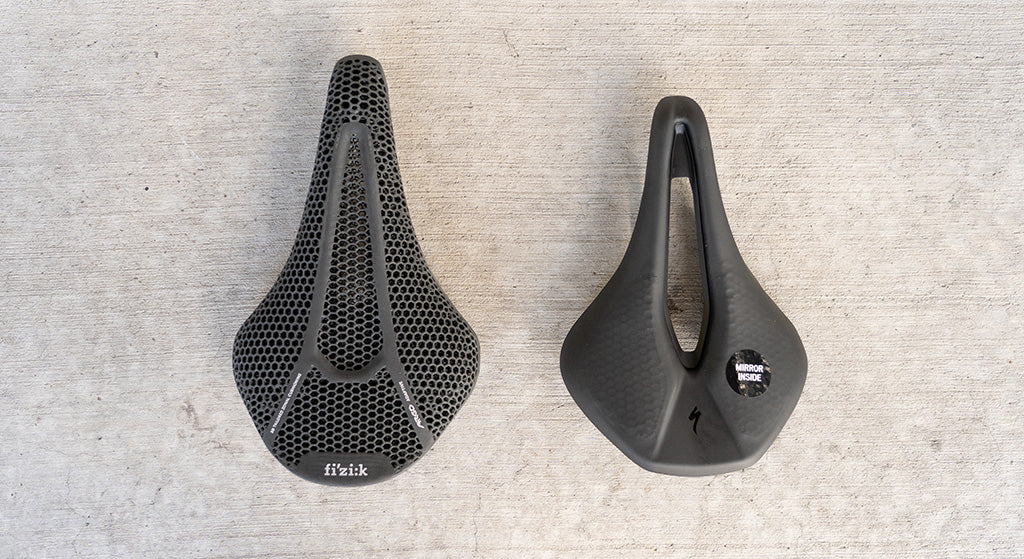

Fizik was the first industry player to jump in the 3D saddle game, having launched the Antares Versus Evo 00 Adaptive back in 2019. Others have joined since then, most notably Specialized, with the “Mirror” version of their proven and popular snub-nosed Power saddle line hitting the market shortly after the Fizik. Specialized and Fizik both now have multiple models at various price points rounding out their 3D printed offerings. Let’s take a quick look at how they go about it and what sets the two brands apart.

Fizik - High-tech guns a’ blazin!

Dubbed “Adaptive”, Fizik’s 3D printed technology made a big visual splash when it hit the market in their more traditionally shaped Antares Versus Evo 00 Adaptive saddle. Initially offered in a “WestWorld-esque” gray-green color, the open-cell 3D printed matrix definitely stood out. Even the full black models that followed later still make a strong visual statement that this saddle is something out of the ordinary. What you see is what you sit on, with the printed polymer construction fully exposed to the eye. The higher-end versions of Fizik’s saddles feature unidirectional carbon composite construction in both the shell that supports the printed padding layer, as well as the carbon rails underneath. The full open-cell polymer layer in Fizik’s Adaptive saddle line keeps the rider well planted, with the idea in mind that with the padding density properly targeted the rider should be able to stay relatively put. Check out Fizik Adaptive saddles here.

Specialized - A non-traditional, more traditional approach

As Fizik hit the 3D scene with the long-standing, well liked Antares shape, Specialized entered the 3D printed superhighway with their wildly popular snub-nose “Power” saddle shape. The S-Works level Power Pro was the first Specialized saddle to receive what they would call their “Mirror” 3D printed technology. As 3D printed saddles aim to provide an optimized platform, it makes sense that Specialized would base their initial offering on a saddle shape that they feel is optimized as well.

The short nose and dramatic taper of the Pro shape aim to provide a universally comfortable, supportive platform that works well under a wide variety of riders. Specialized also treats the outermost aspect of their MIrror saddles a little differently, having engineered more of a “cover layer” or sheath over the open-cell 3D printed matrix. The entire outer padding layer is still indeed one solid mass, but the finished area that you see and feel is smoother and easier to move around on than the pure open-cell texture. Visually, this looks just a bit more like saddle surfaces that we’re used to seeing. The high-end versions of the Mirror saddles feature TexTreme carbon fiber shells and rails, with a more traditional and visually striking carbon weave. Check out Specialized Mirror saddles here.

Non-blazing saddles - How do they stack up?

More options are generally always better, and it’s great to see these two key players offer up some great choices. The manufacturing and design differences between Specialized and Fizik’s 3D printed saddles are subtle for the most part, but one in particular stands out.

The aforementioned open-cell finished layer of the Fizik Adaptive saddles is definitely “stickier” than the smoother, more covered looking layer on the Specialized Mirror models. This translates to the Mirror saddles being easier to move around on, if that’s how you ride. Even with 3D printing optimally targeting the padding density to reduce the need to adjust your riding position, some riders prefer to shift around on the saddle, especially off road. The Adaptive saddles make shifting position a bit harder, but many riders will be just fine with that.

As mentioned earlier, the carbon elements in both brand’s upper-end 3D saddles differ a bit, but it primarily comes down to an aesthetic battle. The unidirectional carbon composite in the Fizik saddles looks smooth and sleek, whereas the woven material in the Specialized saddles screams “carbon!”. Both look great and provide an ultra-strong, ultra-light platform. They’re also ultra-expensive, there’s not much talking around that fact.

In good news for many cyclists however, both brands have introduced 3D printed models at more reasonable price points and have both added additional saddle shapes to their lineups. Fizik has added their short-nosed Argo shape to the Adaptive series, and Specialized offers the more traditional shaped Ronin EVO with their Mirror technology. The more mid-range priced versions of both brand’s 3D printed saddles feature alloy rails and plastic shells supporting the 3D polymer seating surface.

Will they fix everything for everyone?

Not quite… When a 3D printed saddle works, it’s nothing short of amazing. You’ll most likely be able to ride longer, stronger and with less fatigue than on a traditionally padded saddle. As amazing as 3D printed saddles are though, the right saddle choice comes down to the shape and proper fit. For instance if the Antares or Pro shape works for you in their standard versions, the 3D printed version will make things all the better. If a saddle doesn’t work for you, the 3D printed version will only provide a costlier version of the same experience.

If you’re thinking about taking the 3D plunge, we’d love to help you make the right call. Reach out to us at the shop or online with any questions and we can help get you set up with the right saddle. The cycling world is constantly changing and we’re here to help!